Ask Doctor Waterjet

Waterjet Maintenance Tip

How to Extend Component Life, Improve Cutting Performance, and Reduce Costs

Proper waterjet maintenance is essential for ensuring consistent cutting quality, minimizing downtime, and reducing operating costs. Regular maintenance not only extends the life of critical components but also improves overall machine efficiency and reliability.

Below are essential waterjet maintenance tip every operator and maintenance technician should follow.

1. Inspect the Orifice and Mixing Tube Regularly

The orifice and mixing tube (focusing tube) are wear parts that directly affect cutting accuracy.

Maintenance tip:

-

Check for wear, cracks, or chipping

-

Replace worn components before cut quality degrades

-

Use high-quality orifices and mixing tubes to extend service life

Worn components increase abrasive consumption and reduce precision.

2. Monitor Abrasive Quality and Flow

Inconsistent abrasive flow leads to poor cutting performance and uneven edges.

Best practices:

-

Use clean, high-quality garnet

-

Keep abrasive dry and free from contamination

-

Check abrasive feed lines for blockages or leaks

-

Calibrate abrasive feed rates regularly

3. Maintain Proper Water Quality

Poor water quality accelerates wear and damages high-pressure components.

Waterjet maintenance tip:

-

Use proper filtration systems

-

Monitor water hardness and contaminants

-

Replace filters on schedule

Clean water protects seals, valves, and the cutting head.

4. Inspect High-Pressure Seals and Plumbing

High-pressure seals and tubing are critical for safe and efficient operation.

Check regularly for:

Early detection prevents costly breakdowns and unplanned downtime.

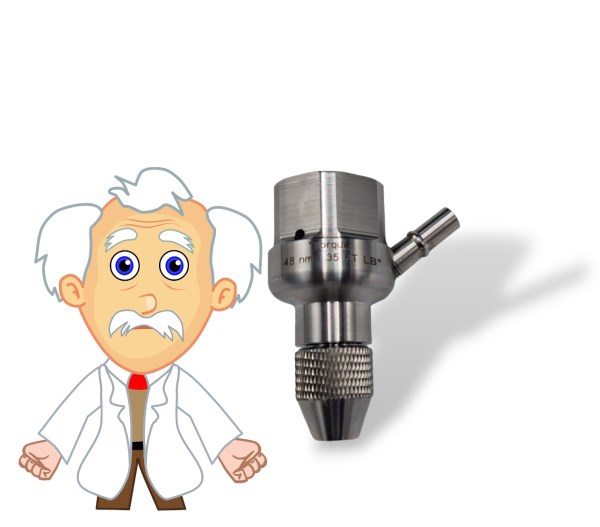

5. Keep the Cutting Head Clean

A clean cutting head ensures consistent abrasive mixing and jet alignment.

Best practices:

6. Follow Preventive Maintenance Schedules

Preventive maintenance is more cost-effective than reactive repairs.

Recommended actions:

-

Follow manufacturer service intervals

-

Keep maintenance logs

-

Replace wear parts proactively

-

Train operators on daily inspection routines

7. Optimize Cutting Parameters

Incorrect cutting settings increase wear and reduce efficiency.

Maintenance tip:

-

Use proper pressure, speed, and abrasive flow for each material

-

Avoid overloading components

-

Adjust parameters when cutting thicker or harder materials

Benefits of Proper Waterjet Maintenance

? Longer component life

? Improved cut quality

? Reduced abrasive consumption

? Lower operating costs

? Increased machine uptime

Final Thoughts

Consistent waterjet maintenance is key to achieving reliable performance and maximizing return on investment. By following these waterjet maintenance tips, operators can prevent common issues, improve efficiency, and keep their waterjet system running at peak performance.

You find all you need for you maintenance need here