Ask Doctor Waterjet

Why Filters Are Essential in Waterjet Cutting Systems

Filters play a crucial role in the operation of waterjet cutting systems for several important reasons. Understanding their significance can help you maintain efficiency and prolong the lifespan of your equipment. In this article, we will have an in-depth look at why filters are essential in waterjet cutting.

Protecting the High-Pressure Pump

The high-pressure pump is one of the most critical and expensive components of a Waterjet system. Filters are vital for:

Ensuring Nozzle and Orifice Integrity

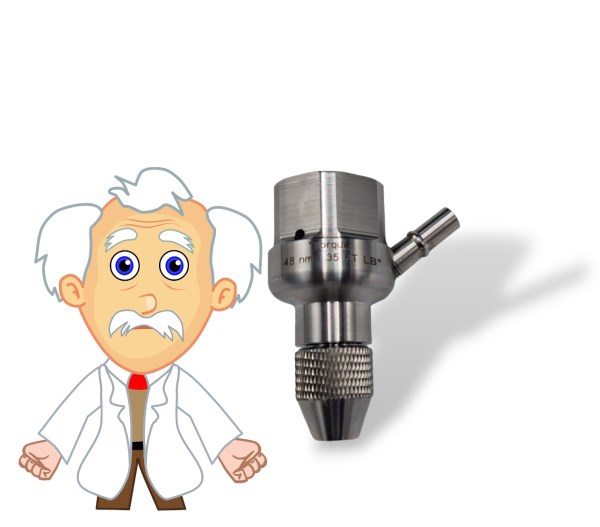

The orifice and nozzle of a waterjet cutter feature tiny openings, often made from sapphire, ruby, or diamond. Filters contribute to:

- Preventing blockages: Proper filtration prevents debris from clogging these tiny openings.

- Maintaining precision: Clean water is essential for preserving the precision of the waterjet stream, as impurities can alter flow characteristics and affect cut quality.

One such filter are the short stop filter.

Improving Cutting Quality

Filters play a crucial role in enhancing the quality of cuts produced by a waterjet system. Clean water is essential for achieving optimal results, such as:

- Consistent performance: Filters ensure a steady supply of clean water, which is crucial for consistent cutting results.

- Smooth cuts: Impurities can lead to rough or jagged edges on cut materials; clean water guarantees smooth and precise cuts.

Reducing Wear on Components

Proper filtration significantly reduces wear and tear throughout the waterjet cutting system, specifically:

- Protecting abrasive systems: Clean water minimizes abrasion on components that come into contact with the abrasive materials, extending their lifespan.

- Minimizing overall maintenance: Regular filter maintenance and replacement leads to less wear on other system components, reducing the frequency and cost of overall system maintenance.

Ensuring Safety

Safety is paramount in any manufacturing environment, and filters play a crucial role in ensuring safe operations. By removing particulate matter from the water, filters help prevent blockages that could lead to dangerous pressure build-up within the system. This proactive measure not only protects the equipment but also enhances the safety of the entire operation.

Types of Filters Used in Waterjet Cutting Systems

To achieve optimal filtration various types of filters are employed. these types are:

- Pre-filters: Remove larger particulates before they reach the high-pressure pump.

- Fine filters: Eliminate smaller particles to ensure a clean water supply.

- Desalination and softening filters: Used to remove dissolved minerals in hard water areas.

Unlocking the Full Potential of Waterjet Cutting with Effective Filtration

In summary, filters are essential for maintaining efficiency, precision, and longevity in waterjet cutting systems. They protect critical components while enhancing overall operational safety.

Ready to enhance your machining capabilities? Explore our range of high-quality abrasive cutting heads today! This version improves flow while keeping your original points intact.

Contact us today