Ask Doctor Waterjet

What is Waterjet Cutting?

Waterjet cutting is a versatile method that uses a powerful water jet to cut through various materials. Thanks to its high precision and the fact that it does not generate heat, this technology is popular in industries, such as aerospace, automotive, and electronics.

How Does Waterjet Cutting Work?

Waterjet cutting operates by forcing a thin stream of water through a nozzle at extremely high pressure, typically between 3,800 and 6,200 bar. If and when it is needed, an abrasive material, such as garnet sand, is added to cut through harder materials.

Two Types of Waterjet Cutting

There are two types of waterjet cutting: pure waterjet cutting and abrasive waterjet cutting.

- Pure waterjet cutting uses only water and is suitable for soft materials like plastic, rubber, and foam.

- Abrasive waterjet cutting involves adding abrasive materials to cut through metals, stone, glass, and ceramics.

Equipment Used

To achieve high precision and efficiency, advanced equipment is required. Waterjet cutting relies on an interaction between different components that generate and control the powerful water stream. The key components are:

- High-pressure pumps that generate the high pressure required for cutting.

- The cutting head contains a orifice made of diamond or sapphire to withstand the pressure.

- CNC control system that programs and controls the cutting process with high precision.

Waterjet Cutting Process – Step by Step

- The material is placed on the cutting table.

- The cutting path is programmed into the CNC control system.

- The pump generates the required pressure.

- The waterjet is directed and cuts according to the settings.

- The finished workpiece is cleaned and inspected.

Advantages of Waterjet Cutting

- Waterjet cutting does not generate heat, meaning there is no risk of hardening or deformation.

- This cutting method is environmentally friendly as it does not produce smoke or harmful gases.

- With high precision, complex shapes with a tolerance of ±0.1 mm can be achieved.

- Waterjet cutting is a versatile method that can cut almost any material.

- Waterjet cutting results in minimal material waste and efficient use of raw materials.

Applications

Materials That Can Be Cut

- Metals such as steel, aluminum, and titanium.

- Plastics and composite materials.

- Glass and ceramics.

- Stone and concrete.

Industries That Use Waterjet Cutting

- Aerospace and aviation.

- Automotive industry.

- Electronics and medical technology.

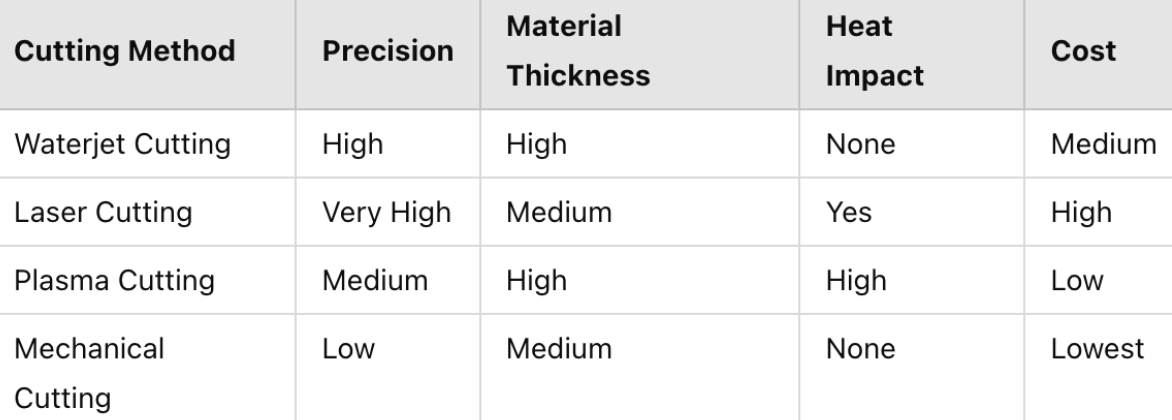

Waterjet Cutting Compared to Other Cutting Methods

A Cost-Effective Method

Although the investment cost is higher than other methods, waterjet cutting can be an economically beneficial choice in the long run. The minimal material waste, low need for post-processing, and ability to cut a wide range of materials with high precision make the method cost-effective in many applications. Additionally, it is a cutting method that can reduce waste and optimize material usage, further contributing to lower total production costs.

Is Waterjet Cutting the Right Choice for You?

Waterjet cutting is used in industrial manufacturing, product development, and custom design to create precise cuts in various materials. The method offers high precision and does not alter the material’s properties through heat. Waterjet cutting can also be a great option for those looking for a flexible, efficient, and environmentally friendly method.

Are you curious to know more about how waterjet cutting can be applied to your business? Contact us at AQUALON – we are happy to help!

Contact us today!