Ask Doctor Waterjet

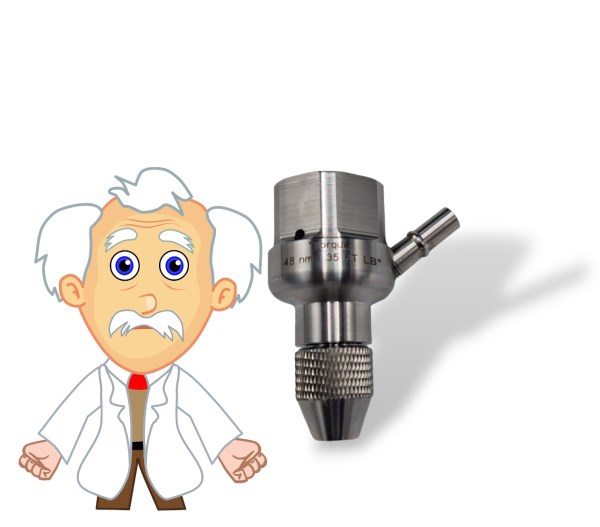

How Does an Abrasive Waterjet Head Work?

An abrasive waterjet head is a key component of a waterjet cutting system. It combines ultra-high-pressure water with abrasive particles to create a powerful cutting stream capable of cutting hard materials with high precision.

Step-by-Step: How an Abrasive Waterjet Head Works

1. High-Pressure Water Generation

The process starts with a high-pressure pump that pressurizes water to extremely high levels, typically between 30,000 and 90,000 psi. This pressure provides the energy needed for cutting.

2. Orifice (Jewel) Nozzle

The pressurized water flows through a small orifice made from durable materials such as sapphire, ruby, or diamond.

The orifice focuses the water into a high-velocity jet.

3. Abrasive Introduction

An abrasive material—most commonly garnet—is fed into the cutting head. The abrasive is drawn into the water stream using a Venturi effect, ensuring consistent mixing.

4. Mixing Chamber

Inside the mixing chamber, the water and abrasive combine into a powerful cutting stream. Proper mixing is essential for maintaining cutting efficiency and accuracy.

5. Focusing Tube

The water-abrasive mixture passes through a focusing tube, which accelerates and aligns the stream before it exits the cutting head. This is where the cutting power is fully formed.

6. Material Cutting

When the abrasive waterjet exits the nozzle, it strikes the material at very high speed. The abrasive particles erode the material along a programmed CNC path, creating precise cuts without heat.

Key Benefits of Abrasive Waterjet Cutting Heads

-

Cold cutting process (no heat-affected zone)

-

High precision and accuracy

-

Suitable for thick and hard materials

-

Minimal material distortion

-

Versatile across many industries

Why Abrasive Waterjet Heads Matter

A high-quality abrasive waterjet head ensures consistent cutting performance, longer component life, and reduced operating costs. Regular maintenance and proper setup are essential for optimal results.

Are you curious to know more about how Abrasive waterjet cutting can be applied to your business? Contact us at AQUALON – we are happy to help!