Ask Doctor Waterjet

Waterjet maintenance 101 - How to extend the life of your cutting system

Waterjet cutting systems are powerful tools widely used in manufacturing, metalworking, and other industries for their precision and versatility. Like any complex machinery, waterjets require regular maintenance to perform at their best and ensure a long operational life. Proper upkeep not only keeps your system running efficiently but also reduces unexpected downtime and costly repairs.

Proper maintenance routines is the key to keeping any waterjet system in top condition. Knowing when and how to replace waterjet spare parts can make all the difference in how long your equipment lasts and how reliably it performs.

Understanding your waterjet system and it’s maintenance needs

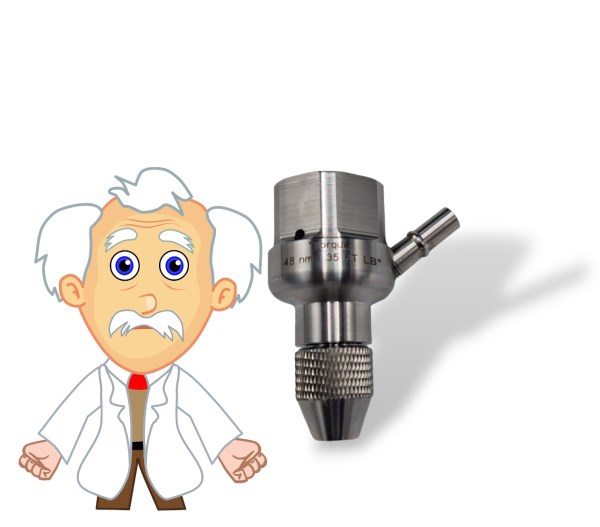

Waterjet systems operate by forcing water at extremely high pressure through a small nozzle to cut a wide variety of materials. The core components include the high-pressure pump, cutting head, nozzles, seals, valves, and the abrasive delivery system (if you use abrasive waterjet cutting).

Each part is subject to wear due to the harsh conditions involved. For instance, nozzles and focusing tubes degrade over time as they handle high-velocity water and abrasive particles. Similarly, seals and valves can wear out or leak, impacting system pressure and cutting accuracy.

Regular inspection and maintenance are critical for identifying early signs of wear or damage. Neglecting this can cause decreased cutting quality and may even lead to damage of more expensive components such as the high-pressure pump.

It is important to follow manufacturer guidelines for maintenance schedules but also to customize your approach based on your system’s usage intensity. Systems that operate continuously or cut tougher materials will require more frequent checks and part replacements.

Key maintenance practices to extend system life

Proper maintenance involves a combination of daily checks, scheduled part replacements, and system cleaning. Here are the most important areas to focus on:

Routine inspections

Daily visual checks of the cutting head, seals, and hoses help catch leaks or abnormal wear early. Keep an eye on pressure gauges to ensure the system operates within recommended parameters.

Nozzle and focusing tube replacement

These consumables wear down with use and should be replaced as soon as you notice reduced cutting performance or visible damage. Using high-quality waterjet spare parts ensures consistent cutting precision and reduces wear on other components.

Seal and valve maintenance

Worn seals cause pressure drops and leaks. Regular replacement based on usage prevents damage to pumps and reduces maintenance costs over time.

Abrasive system cleaning

For abrasive waterjet systems, abrasive delivery lines and mixing chambers should be cleaned regularly to avoid clogging and uneven abrasive flow. The cut quality risks being compromised if not.

Water quality management

The purity of water used is important as well. Contaminated or hard water can lead to scaling and blockages. Installing filtration systems and monitoring water quality extends the life of the pump and other components.

Lubrication and pump care

Pumps require lubrication according to manufacturer specifications to avoid premature wear and failure. Keep detailed maintenance logs to track part replacements and system performance over time.

By adhering to these practices and using high-quality waterjet spare parts, you maximize system uptime and reduce the risk of costly breakdowns.

Keep your waterjet cutting system performing – contact us for expert support

Maintaining your waterjet system is essential to ensure consistent performance and extend its service life. Investing in quality waterjet spare parts and following a regular maintenance routine reduces downtime and protects your equipment.

For professional advice, reliable spare parts, and expert servicing, contact us at Aqualon Waterjet Technology. Our knowledgeable team supports you with tailored maintenance solutions and genuine components designed to keep your waterjet system running smoothly year after year.