Ask Doctor Waterjet

How does a cutting valve work – and why is it so important?

When it comes to waterjet systems, even the smallest component can make a major difference in performance and reliability. A good example is the cutting valve. While pumps and cutting heads often get most of the attention, the cutting valve is just as critical for keeping operations smooth and safe.

Understanding how it works and why it is so important can help operators make smarter decisions about maintenance and replacements.

What is a cutting valve?

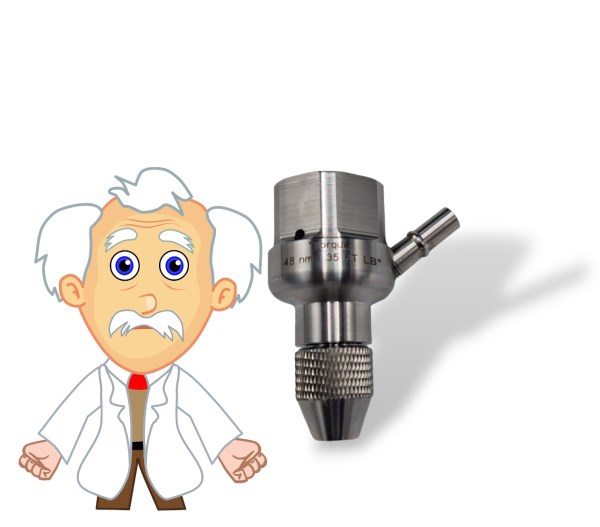

A cutting valve is the component that controls the flow of high-pressure water to the cutting head in a waterjet system. It opens and closes the stream of pressurized water, ensuring that cutting begins and stops exactly when the operator intends. Because water cutting involves extreme pressures, cutting valves must be engineered to handle enormous stress without leaking or failing. Valve bodies, seals, and actuation mechanisms are designed to provide precise control while withstanding constant cycles of high-pressure operation.

How a cutting valve works

The working principle of a cutting valve is straightforward: it acts as a high-pressure switch for the waterjet stream. When activated, it allows water to flow through the nozzle at cutting pressure. When closed, it stops the stream instantly.Inside the valve body, durable seals and plungers create a tight closure when the valve is not engaged. Upon activation, hydraulic or pneumatic actuation forces the valve open, directing high-pressure water toward the cutting head. Because cutting valves are exposed to extreme wear, they are built with hardened materials and replaceable parts to ensure long-term reliability. This precise control allows operators to:

- Start and stop cuts with high accuracy

- Prevent unnecessary water and abrasive waste

- Protect the cutting head from unintended stress

- Ensure consistent cut quality even during long production runs

Why the cutting valve is so important

The cutting valve is often called the "heart of the cutting head," and for good reason. Its role goes far beyond simple on/off control; it directly affects productivity, safety, and component life.

Ensuring cutting precision

Without a responsive cutting valve, cuts may start late or stop unevenly, leading to wasted material and reduced accuracy. A reliable cutting valve keeps cuts sharp and consistent.

Extending pump and nozzle life

By controlling water flow effectively, the cutting valve reduces unnecessary strain on the pump, nozzles, and orifices. This minimizes wear and extends the lifespan of other high-cost components.

Reducing downtime

Faulty valves are one of the most common causes of production interruptions in waterjet systems. Regular maintenance and timely replacement of cutting valves prevent unexpected breakdowns and costly delays.

Protecting operators

Handling water at extreme pressure is inherently risky. A malfunctioning cutting valve can cause uncontrolled water discharge, increasing safety hazards. Reliable valves provide an extra layer of operational safety.

When to replace a cutting valve

Like all high-pressure parts, cutting valves wear out over time and must be replaced periodically. Key signs that a replacement may be needed include:

- Leaking seals – Water escaping from the valve body or actuation system.

- Slower response times – The valve does not open or close as quickly as expected.

- Inconsistent cutting quality – Cuts show irregular edges or unexpected variations.

- Unusual noises or vibrations – Audible signs that internal components are worn.

Using high-quality spare parts ensures that replacements restore full functionality and reliability. For operators with different systems, this includes compatible parts for BFT cutting heads and KMT cutting heads, making it easy to keep your machine running at peak performance.

Aqualon – your partner for cutting valves

Although small compared to pumps or cutting heads, the cutting valve plays an important role in the performance and safety of any waterjet system.

If you want to make sure your waterjet runs at peak efficiency, don’t hesitate to contact us at Aqualon. We provide high-quality cutting valves and spare parts compatible with BFT and KMT systems. Our team of experts are ready and more than happy to help you.